In order to enable safe and reliable shut-off even at temperatures below -100°C, Hartmann has developed various ball valve designs with construction features and materials suitable for low temperatures. Soft sealing valves often reach their limit when the main seal between ball and housing (seating) fails. The soft material contracts at low temperature and as a consequence becomes hard or brittle. However, the Hartmann metallic sealing ball valves are not effected by the low temperature, because the ball and seats are matched, and the metallic seals are not subjects to embrittlement and contraction. The medium ethylene, which is used as an important raw material for the chemical industry in the production of polyethylene, ethylene oxide or styrene amongst others, demands very special shut-off valves. Ethylene is frequently conveyed at high pressures.

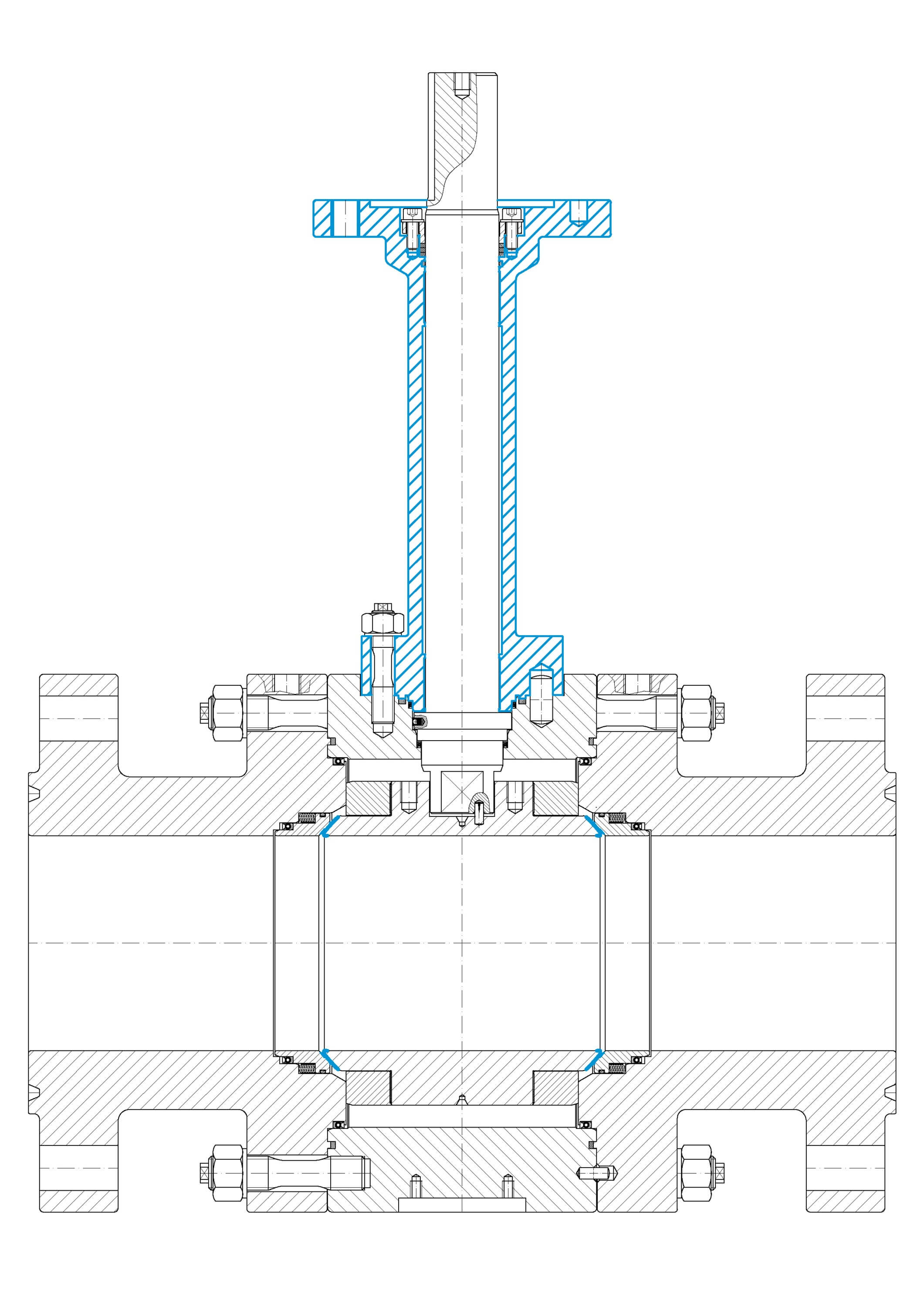

The Hartmann ball valves deployed in various plants around the world have a pure metallic sealing system and are equipped with suitable high quality coatings. The special processing of the coated parts ensures that the valves are gas-tight even at high ethylene pressure of 210 bar. In some plants the ethylene is also present at -110°C. In such cases, low temperature qualified materials are used. To guarantee the seal at the actuating shaft, the shaft is extended and the gas tight sealing is set off the areas exposed to extreme temperatures. Due to the flammability of ethylene, it is standard that Hartmann ball valves are tested Fire Safe and are antistatic.