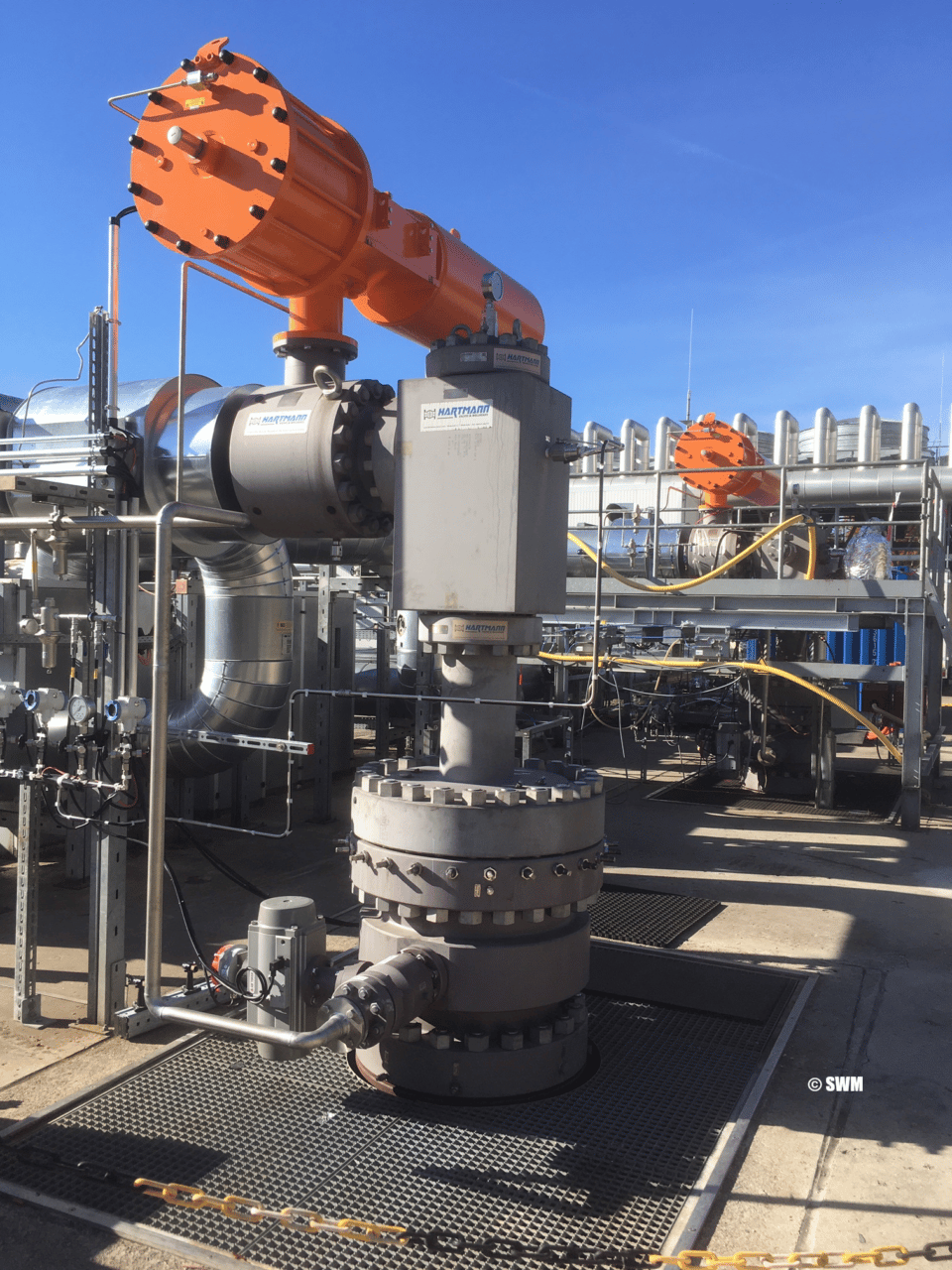

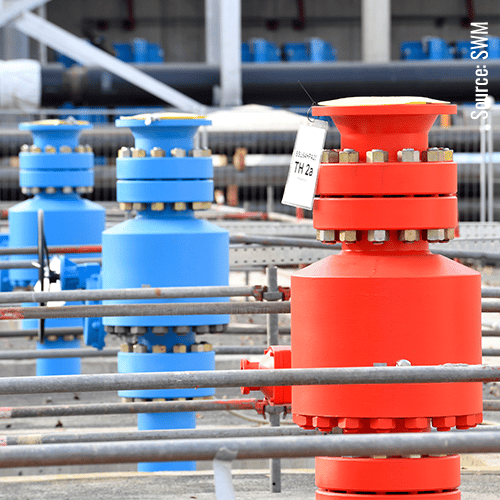

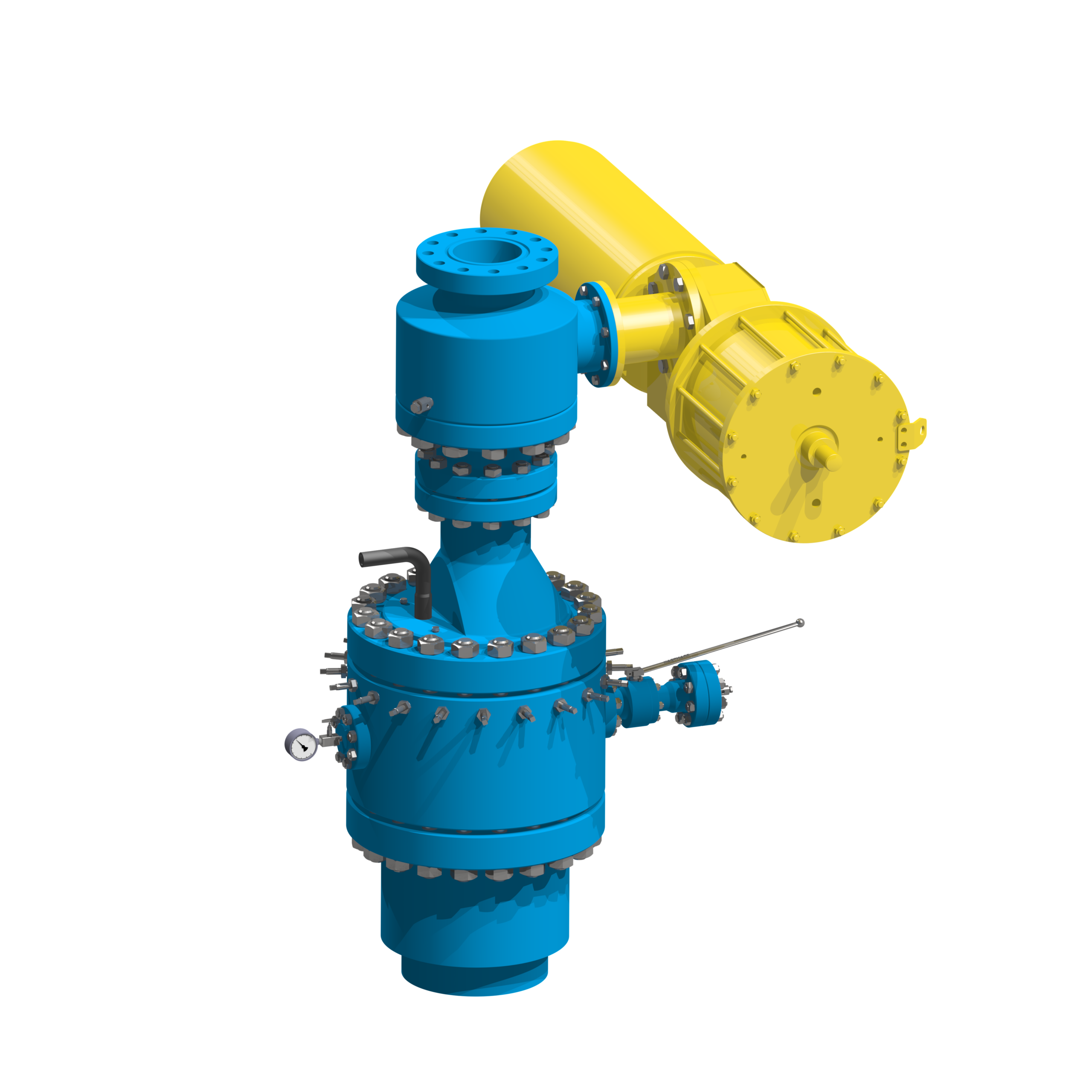

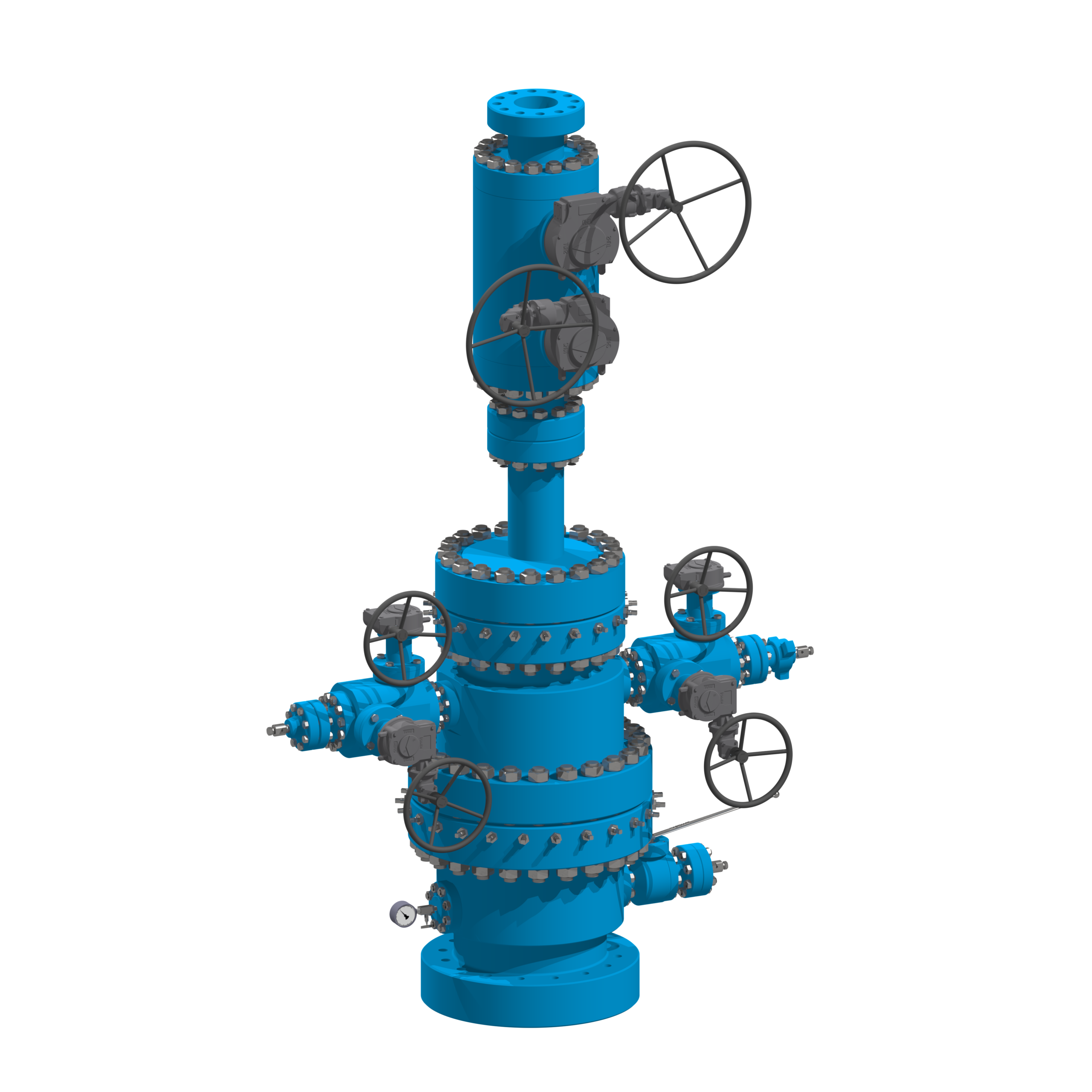

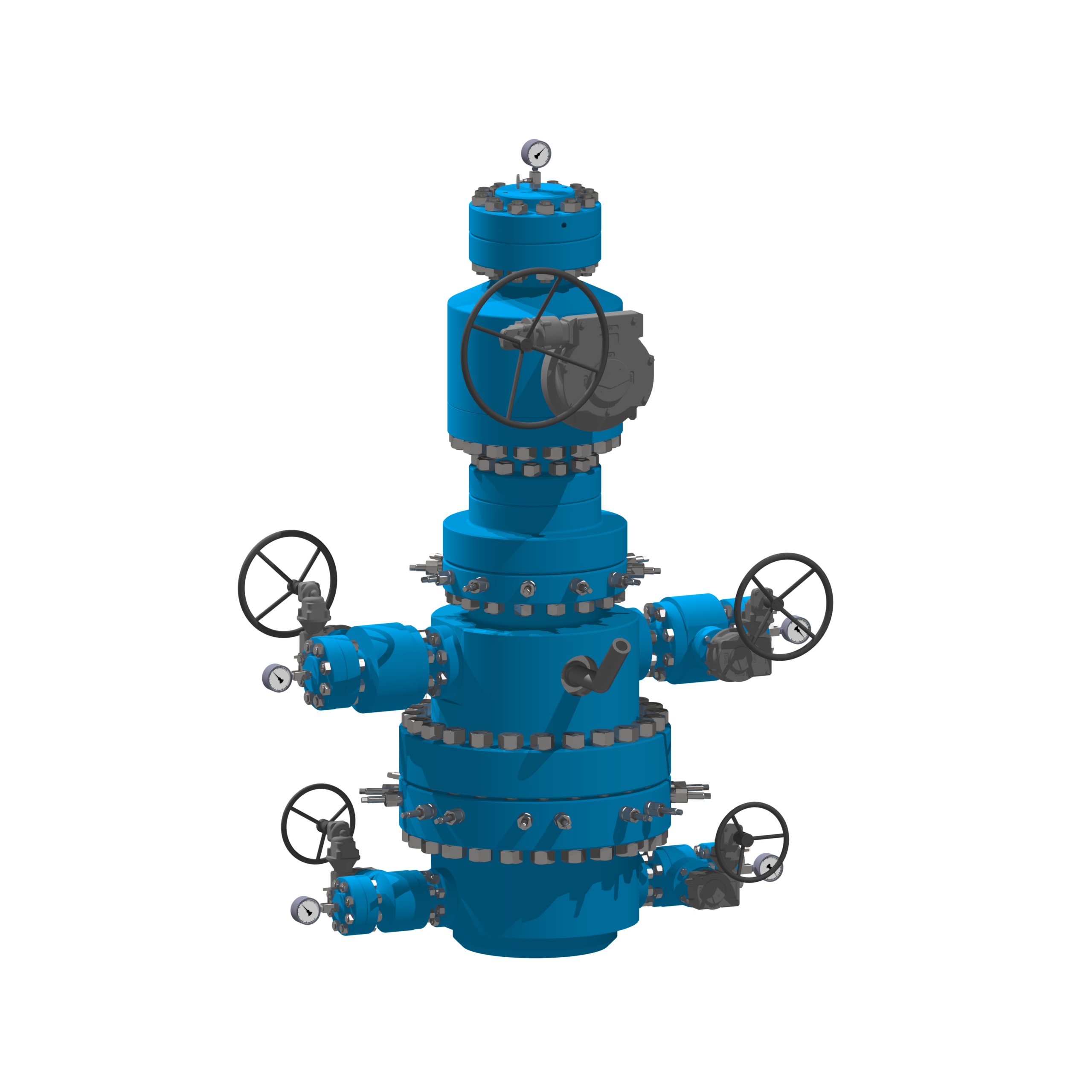

Designed to project-specific requirements and for the highest flow rates and temperatures our geothermal wellheads provide maximum operational safety and plant availability. The use of metal-to-metal ball valves on the wellheads ensures extreme reliability, a long service life and low maintenance requirements.

Since the first pioneering projects in 1978 we have equipped more than 45 projects with a varity of geothermal conditions – including lithium extraction. Hartmann is certified for API 6A, API 6D, API 7-1 equipment and ATEX.

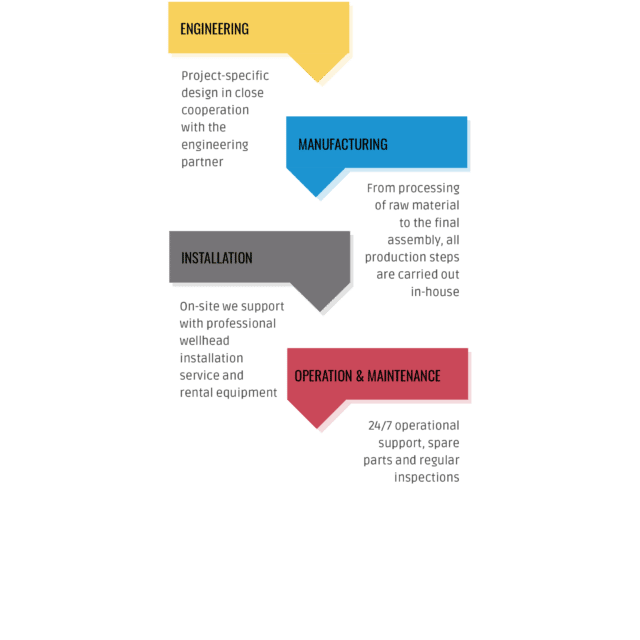

Not only the reliability of the components but also an efficient collaboration between manufacturers, engineering partners and operators are crucial to the success of the projects. Therefore, we support our customers in all project phases – from engineering through inhouse manufacturing, installation on-site, rental equipment, maintenance works such as pump exchange up to the modernisation of existing plants.

Your benefits in Engineering

Meeting the highest standards regarding safety, quality and durability our API wellheads in customised design are made of high-quality materials. Equipped with gas-tight, metal-to-metal sealing ball valves they withstand high temperatures up to 400 °C (752 °F) and pressures up to 10.000 psi. Special designs provide additional safety and economic benefits.

Customised Design Highlights

By default Hartmann geothermal wellheads are equipped with gas-tight ball valves (up to 13-5/8”) which have a metallic sealing between ball and seat to guarantee a high reliability and long service life. In contrast to gate valves, ball valves have the advantage that even with scaling deposits in the pipe they close securely and require significantly less maintenance. Integrated metal-to-metal ball valves offer a higher degree of safety, as they are less likely to blocking, are subject to less wear and do not need to be filled with grease, which could contaminate downstream equipment.

With high safety factor levels Hartmann ball valves are true working valves with throttling function. If required they are provided with flushing connections, e.g. for acidification. Due to their equal overall length, gate valves can be easily replaced at the wellhead. For API 6A ball valves we offer a standard delivery program with short lead times.

Learn more about the advantages of ball valves at the wellhead:

Our experienced service personnel is pleased to offer support in geothermal projects at any time: For extensive jobs such as installation or modification of wellheads, for installation and removal of valves in plants, for assistance during revisions or for maintenance of our products.

Since the first pioneer projects, we have equipped about 45 geothermal projects with wellhead equipment. The map shows an excerpt of geothermal projects in which we are involved with our wellheads. You can request our complete reference list at marketing@hartmann-valves.com.

Or call us or send us an e-mail. We look forward to your inquiry. You can reach us by this phone number: +49 5085 9801 0.