Our high performance valves guarantee the highest level of safety and availability. Designed to individual customer requirements they resist aggressive media, extreme pressures, temperatures and high cycle operations. The metal-to-metal sealing between ball and seat ring provides an especially long service life and minimizes the requirements on maintenance. Besides the conventional ball valve designs we also produce pig valves and twin ball valves for increased safety requirements as well as multi-way ball valves. We develop special tailor made replacements for existing valves.

to the ball valves

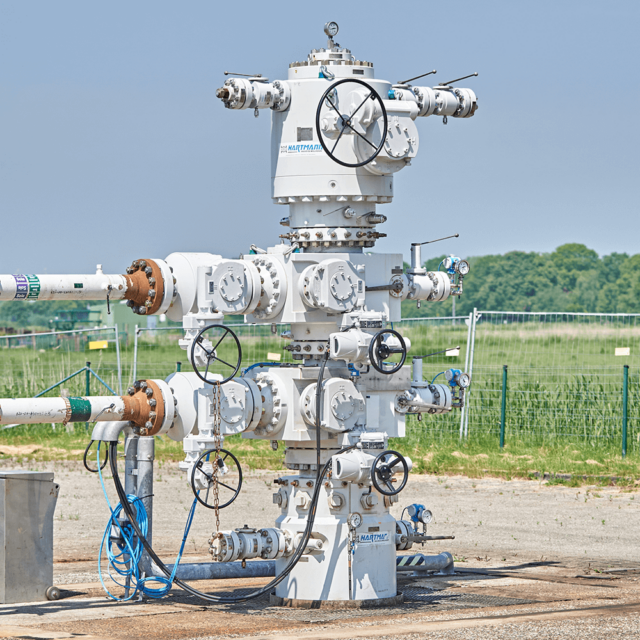

Our API 6A conformant wellheads are designed to the highest requirements and have been deployed for decades in oil and gas production, storage technology and deep geothermal energy. Produced from high quality materials they are equipped as standard with metallic sealing ball valves. Due to an integrated design, not only is the installed height and weight minimized but by saving on flanged connections the safety is improved above all. An experienced service team is available around the clock for assembly service, repairs and maintenance work.

to the wellheads

Our Kelly Valves according to API 7-1 are used as safety valve in the drilling rig. Technically, they are characterised by a wide temperature range from -46°C to +180°C (L/X), class 2 as standard and by their longevity and resistance to higher differential pressures. Hartmann Kelly Valves are available in different lengths, outside and inside dimensions and thread types. They are manufactured and tested according to API specification 7-1 and in compliance with IS0 9001:2015. Hartmann offers an all-round package including short term delivery, stocking in Germany, spare parts and overhaul.

to the Kelly ValvesOr call us or send us an e-mail. We look forward to your inquiry. You can reach us by this phone number: +49 5085 9801 0.