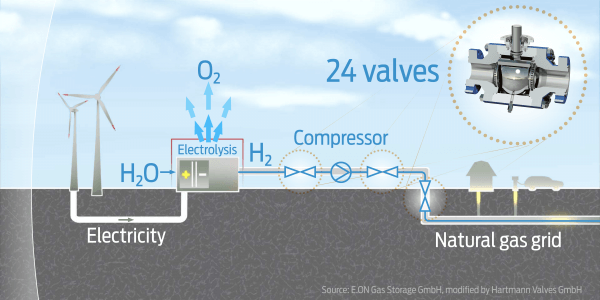

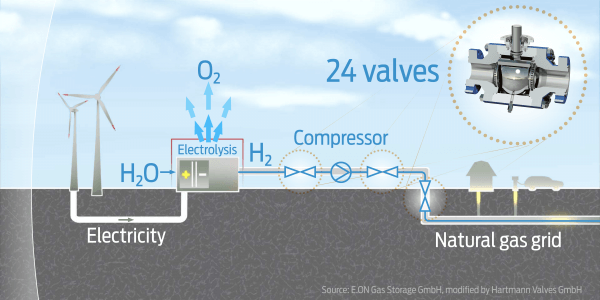

In 2013 Uniper Energy Storage GmbH (UST) brought the power-to-gas plant “WindGas Falkenhagen” successfully on stream. With this project Uniper has been demonstrating, as one of the first companies worldwide, a way how renewable energy can be stored in the natural gas grid in order to make production independent from consumption. For the pilot plant in Falkenhagen (Germany) Hartmann Valves supplied 24 true metal to metal sealing ball valves, designed to meet the excessive demands for service associated with pure hydrogen whilst ensuring maximum safety.

| Project | WindGas Falkenhagen |

|---|---|

| Operator/Engineering | Uniper Energy Storage GmbH |

| Program | Power-to-Gas |

| Inception | October 2011 |

| Start-Up | August 2013 |

| Valves | 24 Shut-off Ball Valves (DN 25 and DN 50 up t o PN 100) |

| Design | seal welded, double barrier (Double-Piston-Design) |

| Flow Rate | max. 360 Nm3/h |

| Operating Pressure | 55 bar |

| Fluid | pure hydrogen |

With Falkenhagen we want to test on pilot-scale how a connection between power and gas grid can be achieved, how we can make the fluctuating renewable energy storable, and how we can integrate green hydrogen in other energy systems and applications.

René SchoofPure hydrogen is a challenging fluid. We have decided to use true metal sealing valves because in technical respect this is the best and safest alternative.

Dr. Helge FöckerDuring the project Hartmann Valves responded to special demands with high flexibility and was convincing with comprehensive expert advice as well as accommodating service.

Sascha Eigelt, division managerOr call us or send us an e-mail. We look forward to your inquiry. You can reach us by this phone number: +49 5085 9801 0.