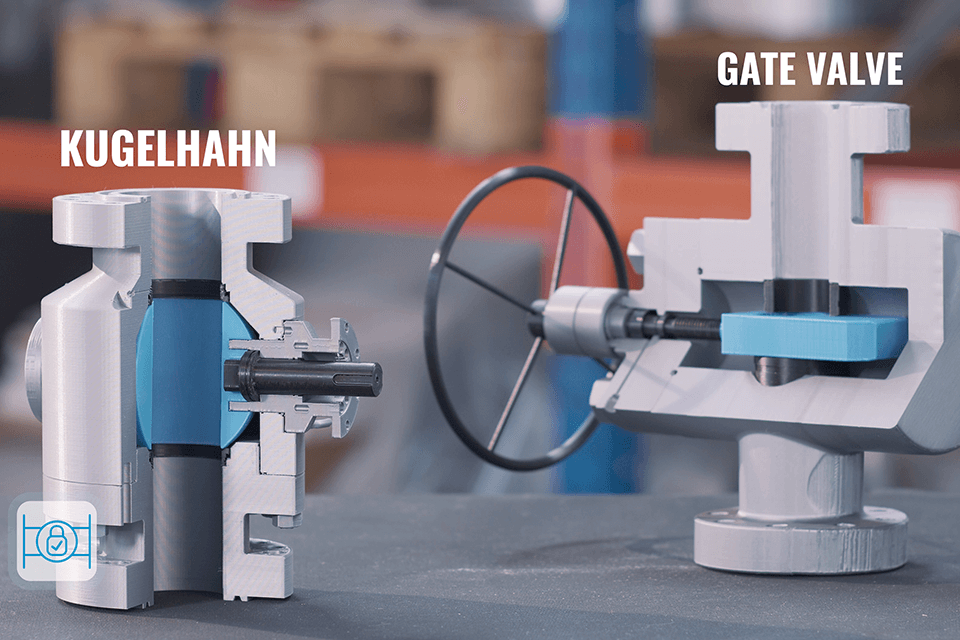

Gate valves have become established for use at the wellhead, but come with some disadvantages. With the API 6A metal-seated ball valves, we offer a replacement in the same overall length, which brings the following advantages:

For ball valves at the wellhead according to API 6A we offer a standard delivery program.

Our delivery times are approx. 12 weeks.

Information Sheet API 6A Ball Valves

Standard Supply Range

Video: Metallic Sealing System

Video: Why Ball Valves instead of Gate Valves?

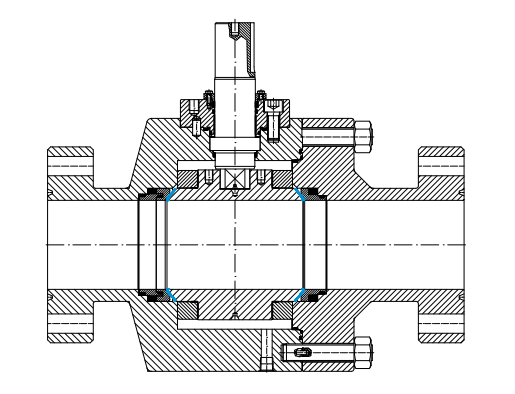

• 2-piece housing

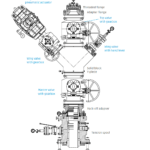

• Type AST with trunnion mounted ball ≥ 2 1/16”

• Type ASF with floating ball for 10,000psi ≤ 2 1/16”

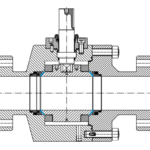

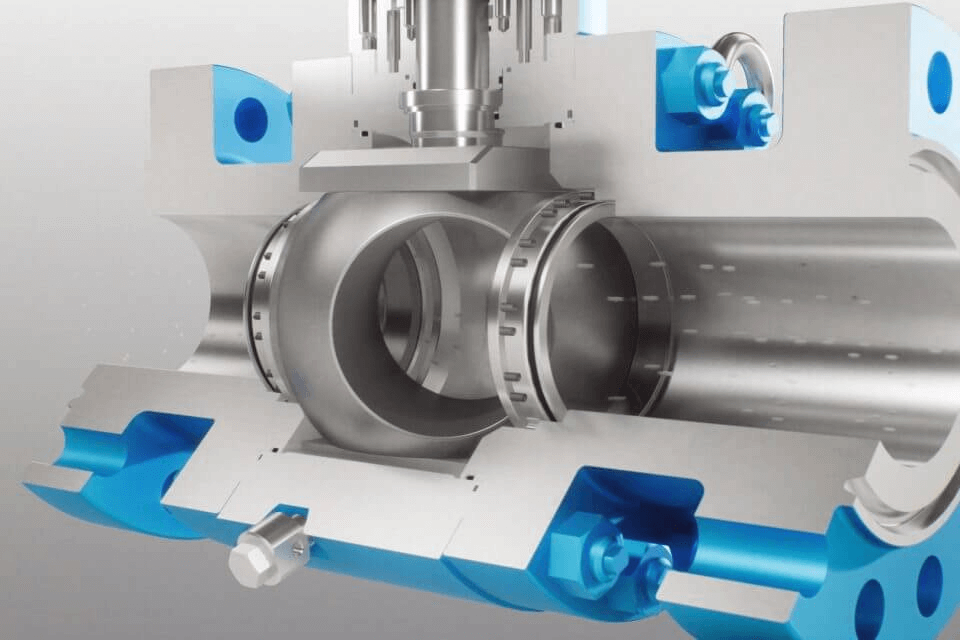

• Metallic sealing system with tungsten carbide hard-faced coating

• Triple shaft seals (type AST)

• Fugitive emission acc. ISO 15848-1 up to +200°C

• Anti-blowout shaft /anti-static design

• Conforms DIN/ISO standard gear mounting

• Position indicator for open position on all ball valves ≥4 1/16”

• Drain port NPT or ISO incl. bleeder plug

• DIB-2 design* (type AST)

*Double Isolation and Bleed 2 (DIB-2) design: has upstream seat equipped with a standard seat ring to

ensure pressure relief of valve cavity in the direction of the well. The downstream seat ring is equipped with

split seat ring to provide a “Double Piston effect” and seals in both directions. –› Double barrier against

well pressure.

• Material class EE-NL

Also, AA, BB, DD; EE-NL (H2S no limit), EE-1.5

• Quality class PSL3 or PSL3G

• Performance level PR1 (PR2 on request)

• Temperature class L/X

L/X also includes N, P, S, T, U and V

• All wetted parts acc. API 6A ductility

• All wetted parts with hardness values acc. ISO 15156 (NACE)

• Light protection primer C2 in acc. DIN ISO 12944-5, RAL 1013 (HV 2)

• Medium protection C3 in acc. DIN ISO 12944-5, RAL 5012 (HV 3)

• High protection C5-M in acc. DIN ISO 12944-5, RAL 5012 (HV 4)

• High temperature resistant aluminium (HV 6)

Other colour systems on request

Our Hartmann Valves API 6A ball valves are available in various designs:

In addition, the seat system is metal-to-metal sealing.

Metal-to-Metal Sealing System in Ball Valves

Metal-to-Metal Sealing System in Ball Valves

Why Ball Valves instead of Gate Valves at the Wellhead?

Why Ball Valves instead of Gate Valves at the Wellhead?

Or call us or send us an e-mail. We look forward to your inquiry. You can reach us by this phone number: +49 5085 9801 0.