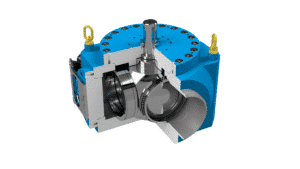

At the Valve World Expo 2022 in Düsseldorf, the Valve Stars Awards were announced in the categories of valves, actuators, seals and automation. In the category “Valves”, Hartmann Valves won with its innovative ball valve design with integrated heating jacket. The new ball valve design is characterised by the integration of the heating jacket into the valve body.

In special applications, the heating of valves is necessary to keep the medium flowable. Traditionally, double jackets for heating the valve are welded to the outside of the valve body. By integrating the heating jacket into the ball valve body, it is possible to eliminate the need for welding on the double jackets and to benefit from the shorter distance between the heating medium and the medium to be heated, because the shorter distance can significantly improve the heat transfer. The purely metallic sealing also ensures that even if solids are contained in the medium, the essential seals (seat rings) are not damaged or destroyed. The compact design allows easy mounting of the bolts and nuts on the connecting flanges.

The heating of valves is particularly necessary for special applications. Heating jackets are used when media must remain fluid. Due to the constant low viscosity of the media, pump capacities can be reduced and damage caused by solidifying solids to the pipeline or the valves can be avoided.

Traditionally, double jackets are welded to the outside of the valve body to heat the media. The new ball valve design from Hartmann Valves integrates the heating jacket into the ball valve body and eliminating the need for welding double jackets. The integrated heating jacket reduces the distance between the heating medium and the medium to be heated, which significantly improves heat transfer.

The purely metallic sealing ensures that even if solids are contained in the medium (such as sulfur cement in the case of liquid sulfur), the essential seals are not damaged or destroyed. The new design provides a space-saving and easy-to-install alternative to the traditional heating jacket system.

For more information, please contact our expert:

Peter Wegjan

p.wegjan[at]hartmann-valves.com

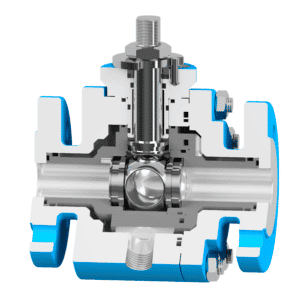

Hartmann Valves launch a new standard in the field of Kelly Valves. As a drill string valve, Kelly Valves are used as a safety valve in the drilling rig. In the event of a possible kick they prevent the medium, by switching the ball to the closed position. The new developed Hartmann Kelly Valves are technically characterised by a wide temperature range from -46°C to +180°C (L/X), class 2 as standard and by their longevity and resistance to higher differential pressures.

After successful use in the Innova Rig drilling unit by long-term customer H. Anger’s Söhne Bohr- und Brunnenbaugesellschaft mbH the Hartmann Valves Kelly Valves were now officially included in the product portfolio. Manufactured and tested according to API specification 7-1 and in compliance with ISO 9001:2015 the Kelly Valves are available in different lengths, thread types and dimensions. The development of the Kelly Valve is based on decades of experience in the oil, gas and geothermal drilling industries and product know-how in the field of special ball valves and wellheads. Thanks to the investment in research and development and the expansion of the product range, Hartmann Valves now offers its customers an all-round package incl. short term delivery, stocking in Germany, spare parts and overhaul with the Kelly Valves.

Hartmann’s Kelly Valve expert Nora Greßies is available for any technical and sales related questions.

Contact person:

Nora Greßies

n.gressies[at]hartmann-valves.com

+49 5141 3841-83

In the north of Lower Saxony, the first phase of the pilot project “H2CAST Etzel” is starting with Hartmann Valves as project partner. In the hydrogen research and development pilot project, the feasibility of large-volume underground hydrogen storage is to be demonstrated and tested in operational storage operation. H2CAST stands for H2CAvern Storage Transition, i.e. the conversion of existing caverns and facilities in Etzel for the storage of hydrogen as a building block for a future energy system.

As a partner of STORAG Etzel GmbH for decades and supplier of wellheads for the oil and gas caverns in Etzel, Hartmann Valves is on board as a project partner. The order is for two wellheads adapted to hydrogen for well protection, including valve technology. Corresponding material suitability and leak tests will also be carried out. The know-how and experience in the field of hydrogen will be of great importance in this project. As a project partner, Hartmann Valves is accompanying Lower Saxony towards the future.

Source of image material: STORAG Etzel GmbH

Graphical overview of the research project “H2CAST Etzel”

The current Etzel cavern facility in Lower Saxony currently comprises 75 oil and gas caverns.

Hartmann wellhead incl. brine discharge head of a gas cavern at the Etzel site. The future hydrogen wellhead for the H2CAST pilot project there will look similar.

On Friday, 08th October 2021, 75 trees were planted near the company’s headquarter in Ehlershausen to mark the 75th anniversary of the Hartmann company.

Initiated by the committed Hartmann NASCH (NAturSCHutz) group and supported by about 35 energetic volunteers, 16 different tree species and a total of 75 trees were planted at the beginning of October. The location of the event was a 2500 m² forest area whose spruces had been attacked by the bark beetle and now had to be reforested. The woodland is located next to the area of the former Hänigser oil fields and is a symbol for the energy and industry change, in line with the anniversary slogan “Together towards the future”.

In bright sunshine, we digged, planted, tied, watered and ate together. Many thanks to all helping hands. Now it’s time to wait and water so the trees continue to grow.

More information about the campaign can be found in the HAZ.

The winners of the Primus Award were announced at the DIAM 2021 in Bochum. In the VALVE category, the winner was Hartmann’s new pigging ball valve, which has been submitted for patent.

The new Hartmann pigging ball valve with multiple safety barrier to the sluice room enables the safe and easy launching and receiving of pigs even with (residual) pressure in the main line. In this new kind of construction, the sluice room is separately closed off by at least two additionally installed seat rings. Pressure gauges are used to monitor the sluice pressure. If the first barrier of the pipeline to the dead storage is leaking, the second barrier seals against the interlock and the sluice gate can still be closed without danger. The design not only simplifies the process of pigging, it also increases safety.

The new design also allows other applications, such as the use of a sieve basket filter. Other options include the use of check valves in the ball, the insertion and removal of measuring equipment, or the placement of control wheel to throttle the flow. The innovative design allows many other applications and is also suitable for hydrogen.