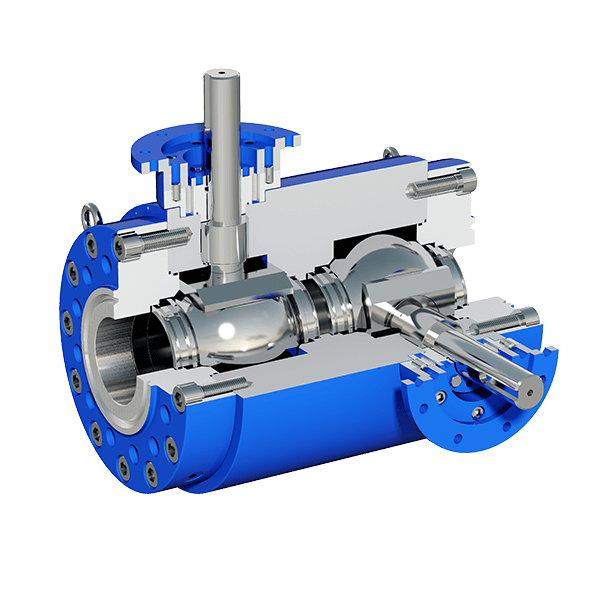

Hartmann Valves ball valves of the TBV series find use when strict safety regulations require a dual pipeline shut-off. Designed for these applications, the Hartmann Valves TBV series combines two complete and independent shut-off systems (“Twin Ball Valve“) in just one housing: 0-bubble seal tight, and testable between the shut-off systems. The compact design facilitates operational reliability, and furthermore helps in saving space and lowering costs due to lowered material demands.

Upon request we manufacture and deliver the ball valves of the TBV series for you:

DGRL 2014/68/EU und API 6D:

API 6A:

Find out which customers use our ball valves successfully.

Show referencesOr call us or send us an e-mail. We look forward to your inquiry. You can reach us by this phone number: +49 5085 9801 0.